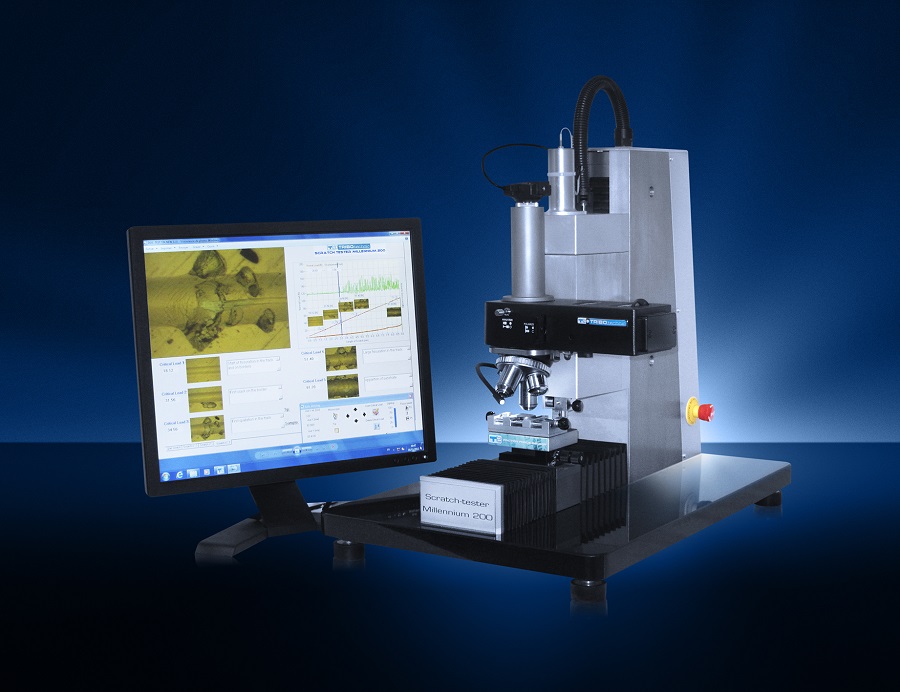

Scratch-Tester Millennium

SCRATCH TESTER MILLENNIUM'S EXCLUSIVE FEATURES:

-

The only scratch tester on the market which responds to the standard ISO 205 02 (formerly 1071-3)

-

Software with function "SMART SCRATCH DISPLAY" : visualization of scratch correlate to applied load. Precise localization of digitized pictures (with indication of load applied to the location of photos) with acoustic emission (option), friction force (option) and loading graphs. Inlay these images on the graph.

-

Software with function "SMART SCRATCH REPORT" : Automatic report with the picture of the scratch and indication of load applied to the location of photos and magnification.Automatic synthesis of all scratch results from each sample.

-

"Do it yourself" calibration kit which conforms to the standard ISO 205 02 (formerly 1071-3)

-

Anti-collision system between a sample, a tip and the objective

-

Traceability and wear check of tips

In accord with Standard EN 205 02 (formerly 1071-3), ASTM C1624, ASTM G171

Scratch test instrument for adherence characterization and scratch resistance for thin coatings and bulk materials.

The scratch-test method consists of scratching on the surface with a diamond tip on which is applied a constant or progressive load.

As the scratching is done the sample moves under the video system, to examine the different kinds of damage done by the tip and correlate it with load applied.

This standard method allows for comparison of different coatings according to substrates, thickness of coatings and preparations of surface before coating and scratch resistance of bulk materials.

We've developed three instruments in order to test different kind of coatings

Thickness from 500 nanometres to 100 microns:

Millennium 50

Maximum load : 50 N

Minimal load : 0,025 N

Millennium 100

Maximum load : 100 N

Minimal load : 0,05 N

Millennium 200

Maximum load : 200 N

Minimal load : 0,1 N

Example of scratch test on TiN PVD coating

Plastic deformation

and longitudinal cracks

at the borders of the

scratch track.

Spallation along the

scratch track border,

both cohesive and

interfacial.

Discontinuous

ductile perforation

of the coating.